...unless you have to. What can you do, the kiln is kaput and needs new______. I know, I fixed it in October, but at Christmas it fizzled out again. There was a broken insulator, the top element came into contact with the kiln jacket and burned out. Luckily the kiln shut itself OFF because....it is too terrible to imagine.

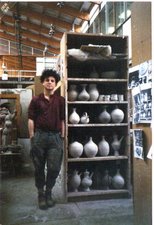

So, I used the baby kiln for a couple of weeks, as you may remember, but the parts are here and I tore the thing apart. As you can see.

Step one: unplug the kiln!

Electric kilns are meant to be repaired, so the instructions are good, plus I have changed parts many times before. The first test with the new element resulted in the kiln alarm bleating, so power off and back into the guts, to find the thermocouple had a problem (it is next to the element just replaced) so cleaned it up, and hey, good as new.

8 comments:

wow Gary

you have some wonderful...crazy...and gorgeous work here...

I adore your Beagle !!!!

Excellent job, Potterman! Now, how large is your pile of stuff to be fired?

well, Gord, quite a few things, but with holidays and firing the baby kiln, the absolutely FREEZING studio and a sore arm, the production levels have been low

Thanks Kim! Kim, folks btw, is quite a mover and shaker in the blog/art world, we're honored to have her visit, yessirree

WOW gary... words like "thermocouple" and being so artistic.. might have to start labeling you as a renaissance guy!

so on avg.. how often do you have to repair these things? is it getting more frequent as they get older?

how often? in theory when parts wear out every two-tree years or more, but this kiln ::grrrr::::

ahh the ol' theory vs reality syndrome

hows the arm now Gary? (much impressed with the big technical terms too) ;)

the arm is better thanks!

Post a Comment